FUCTION AND FEATURES

Product Showcase

PRODUCT CLASSIFICATION

Contact Us

Telephone: +86-29-88341693

Fax: +86-29-88341693

Email: xametalwk@163.com

Website: www.metalwk.com

Add: Room 1005, Block F, Van Metropolis, No.35, Tangyan Road, Hi-tech Zone, Xi'an, P.R.China.

Copper Bar Hydraulic Continuous Drawing Line

Copper bar hydraulic continuous drawing line is used for the continuous drawing process

Keyword:

drawing

continuous

significantly

Category:

Drawing Equipment

Copper Bar Hydraulic Continuous Drawing Line

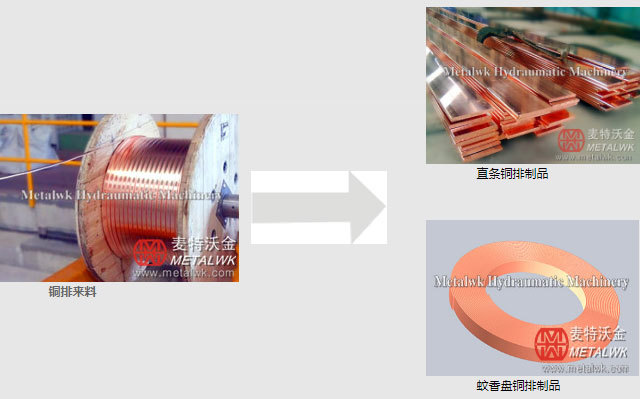

Copper bar hydraulic continuous drawing line is used for the continuous drawing process of coiled copper bars, and at the same time to achieve automatic straightening, automatic lubrication, automatic cleaning, automatic cutting-to-length, automatic discharging and automatic pancake coiling. It's applied to draw continuously and process copper bars and parts of profiled bars, and achieves unlimited length continuous drawing production for products, which is different from general single-cylinder semi-continuous drawing machine and mechanical continuous drawing machine.

This whole production line cans finish the above mentioned procedures automatically and just be operated by 2-3 workers to finish the coiled copper bars with length of thousands meters form extrusion press on one set of drawing machine under the situation of no transferring in plant. No matter how heavy the coiled copper bar is (weight up to 3 ton, or even indefinite length), it just produces a small section of waste copper from the head and the end.

Compared with the traditional drawing method, this continuous drawing method increases the material yield by 6-10%; the production efficiency is reduced from 11-13 person-hours/ton to 2.5-3.5 person-hours/ton; the production floor space is reduced to 1/3 of the total floor space of the traditional drawing method; product quality (including surface bumps, scratches, product side bending, surface gloss consistency, etc.) is significantly improved.

The production line equipment has obtained national patent protection. This patented technology is a continuous and automated copper busbar processing technology. Based on the continuous casting technology and continuous extrusion technology, and organically combined with hydraulic continuous drawing technology, it realizes continuous and automated production of the entire copper busbar production process; this process improves production efficiency, increases material yield, improves product quality, reduces energy consumption, significantly improves the working environment, reduces production floor space, simplifies production management, and achieves good economic and social benefits. The equipment operates stably and reliably, truly realizing modern fully automated operation, saving costs and labor, and greatly improving productivity.

● Continuous drawing without pause with high efficiency

● It’s particularly suitable to pull the tenuous products with high resistance of deformation and moderate drawing speed

● Unlimited for product length;no need drawing in section after cutting for tenuous products; decreasing end making , improving yield rate obviously

● Reducing the workers and labor cost; improving labor productivity

● Reliable equipment running and less workload for maintenance;

● Accurate mold centering and convenient and reliable mould adjustment prevent and avoid bending of products;

● On-line cut-to-length and on-line rewinding can be achieved; high degree of automation; arbitrary figure settings for length of cutting and rewinding;

● Equipped with various sensors that can record and display data such as tensile strength, stretching speed, stretching length and so on.

● Process parameter settings and input is convenient and flexible with friendly man-machine interface;

● The short process for production line and compact structure obviously reduce the occupied area and project investment cost.

Copper bar hydraulic continuous drawing line has been sold to European market and successfully applied into the production line of famous copper processing industries in Spain and Britain.

Previous Page

Previous Page

Online Message

*Note: Please ensure that the information is filled in accurately and keep the communication open. We will contact you as soon as possible.